1. The difference between safety light curtains and safety gratings

Safety gratings and safety light curtains are safety protection devices, mainly used in robots, automation equipment, industrial production lines, etc. occasions to protect the safety of personnel and equipment. Their main difference lies in their physical structure and working principle.

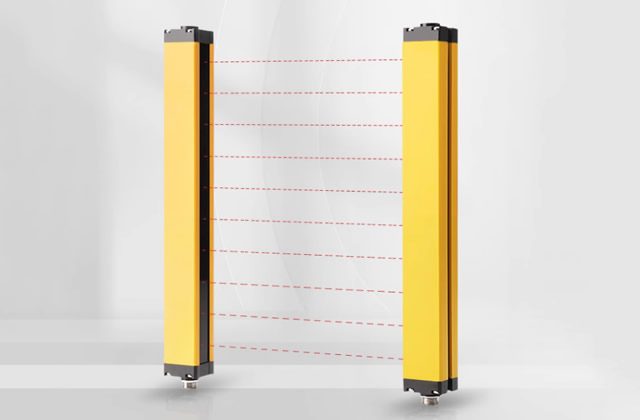

A safety light barrier is a device composed of multiple photoelectric sensors that create a light barrier area that is interrupted when a person or object enters the area, triggering the robot or equipment to stop operating. Safety gratings are usually used to protect small-sized areas and can provide efficient protection in narrow spaces.

In contrast, safety light curtains are flat panels composed of multiple photoelectric sensors that create a flat light curtain. When someone or an object enters the light curtain, the light is blocked, triggering The robot or device stops functioning. Safety light curtains can cover larger areas and are often used to protect large machines or areas.

2. The key role of safety light curtains in automated production

The previous article has briefly understood Now that we know the difference between safety light curtains and safety gratings, let’s focus on the safety light curtains and their key role in automated production!

1. Personnel safety: There may be dangerous areas in automated production environments, such as machine operating areas or assembly lines. Safety light curtains can effectively prevent people from entering these dangerous areas and avoid accidental injuries.

2. No physical barriers required: Compared with traditional physical barriers, safety light curtains do not require actual objects to isolate dangerous areas, making them more flexible and convenient for the production process. Operation and adjustment.

3. Improved production efficiency:Safety light curtains allow automated operations in the production process, reducing manual operations and intervention, thereby improving production efficiency and output.

4. Human-machine collaboration: In some cases, safety light curtains can allow operators to collaborate with machines in safety mode, allowing personnel to work more closely with machines. Machines interact.

5. Quick shutdown: When someone enters the dangerous area, the safety light curtain can quickly stop the relevant equipment to avoid potential accidents andharm.

6. Avoid collisions: For autonomous navigation robots or automated mobile devices, safety light curtains can help avoid collisions with people or other objects.

7. Space saving: Safety light curtains do not require a large amount of physical space, so they can be used in compact work areas without taking up too much space.

8. Strong adaptability: Safety light curtains can be adjusted and configured according to different application scenarios to adapt to different safety distances, heights and regional requirements.

If the website content violates your rights, please contact us to delete it。