The role of the cylinder block

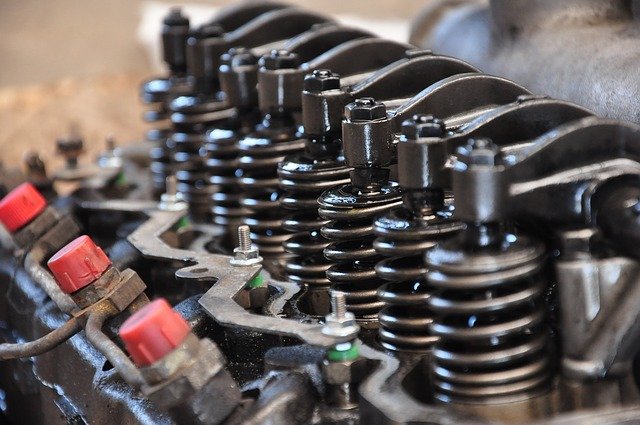

The cylinder block is the main body of the engine. It connects the cylinders and the crankcase into one, and is where the pistons, crankshaft and other parts and accessories are installed. Support skeleton.

The working conditions of the cylinder block are very harsh. It has to withstand the rapid changes in pressure and temperature during the combustion process and the strong friction of the piston movement. Therefore, it should have the following properties:

1. It has sufficient strength and stiffness, small deformation, ensuring the correct position of each moving part, normal operation, and low vibration and noise.

2. It has good cooling performance. There is a cooling water jacket around the cylinder to allow the cooling water to take away heat.

3. Wear-resistant to ensure sufficient service life of the cylinder block.

The arrangement of cylinders

For multi-cylinder engines, the arrangement of cylinders determines the shape and structure of the engine. It also affects the stiffness and strength of the engine cylinder block, and is related to the automobile. the overall layout. There are basically three forms of automobile engine cylinder arrangement:

1. In-line engine

The cylinders of the engine are arranged in a row, usually vertically. But in order to reduce the height of the engine, the cylinders are sometimes arranged tilted or even horizontally. The single-row cylinder block has a simple structure and is easy to process, but the engine length and height are relatively large. Generally, engines with six cylinders or less are single-row. For example, the engines used in Jetta sedans, Fukang sedans, and Hongqi sedans all use this in-line cylinder block.

2. V-type engine

The cylinders are arranged in two rows, and the angle between the center lines of the left and right rows of cylinders is γ<180°. It is called a V-type engine. A V-type engine is similar to an in-line engine. Compared with the engine, the length and height of the body are shortened, the rigidity of the cylinder block is increased, and the weight of the engine is reduced, but the width of the engine is increased, and the shape is complex and difficult to process. It is generally used for engines with 8 cylinders or more. 6 Cylinder engines also have cylinder blocks in this form.

3. Opposed engine

The cylinders are arranged in two rows, and the angle between the center lines of the left and right rows of cylinders is γ = 180°.

What are the structural forms of the cylinder block?

1. General cylinder block

The characteristics of the general cylinder block are: The oil pan installation plane and the crankshaft rotation center are at the same height. The advantages of this type of cylinder block are small height, light weight, compact structure, easy processing, and convenient crankshaft disassembly and assembly, but its disadvantage is poor stiffness and strength;

2. Gantry cylinder block

The characteristic of the gantry cylinder block is that the installation plane of the oil pan is lower than the rotation center of the crankshaft. Its advantage is that it has good strength and stiffness, and can withstand large mechanical loads, but its disadvantages are poor craftsmanship, heavy structure, and difficult processing;

3. Tunnel cylinder block

The main bearing hole of the crankshaft of this form of tunnel cylinder block is integral and uses rolling bearings. The main bearing hole is larger and the crankshaft is loaded from the rear of the cylinder block. Its advantages are compact structure, rigidity and strength. Good, but its disadvantages are high processing accuracy requirements, poor craftsmanship, and inconvenient disassembly and assembly of the crankshaft.

If the website content violates your rights, please contact us to delete it。