1. What is the principle of concrete delivery pump?

Concrete delivery pump adopts electric motor or diesel engine to drive the pumping system, and automatically adjusts the delivery of concrete delivery pump through constant power control of the hydraulic system. Volume, manual control can also be used to select the concrete delivery volume. The pumping system mainly consists of a hopper, mixing mechanism, concrete distribution valve, concrete delivery tank, washing room and main oil tank. The working principle of the concrete delivery pump is:

When the hydraulic system pressure oil enters the main cylinder, the piston rod extends, and at the same time, the pressure oil passing through the sealing circuit connecting pipe causes the other piston rod to retract. When the concrete conveying piston connected to the piston rod of the main oil cylinder retracts, it produces a self-priming effect in the conveying cylinder. The concrete in the hopper is sucked into the conveying cylinder through the slide valve suction port under the action of atmospheric pressure and the boosting effect of the mixing blade. At the same time, under the action of oil pressure, the other main oil cylinder pushes the piston rod of the main oil cylinder to extend and simultaneously pushes the concrete piston to press out the concrete in the delivery cylinder, and enters the concrete delivery pipe through the Y-shaped pipe of the slide valve delivery port. After the action is completed, the system automatically reverses direction to allow the pressure oil to enter another main cylinder to complete another suction and delivery stroke of a different delivery cylinder. Repeatedly, the concrete in the hopper is continuously sucked in and pressure-sent out of the delivery cylinder, and reaches the operating point through the Y-shaped pipe and the pipe connected to the outlet, completing the pumping operation.

2. What are the models of concrete pumps?

Because Concrete delivery pumps vary in function and structure according to different project conditions. According to different functions, concrete delivery pumps can be divided into several types such as boom pumps, vehicle-mounted pumps, integrated mixing pumps, and tow pumps. The corresponding abbreviations of different types are also different. For example, HBT represents a tow-type concrete pump, and CHB represents a truck-mounted concrete pump. Common concrete pump models are:

1. Electric motor ConcreteTransfer pump model

Illustration: such as HBT60SEA-1816——HBT (trailed concrete pump), 60 (maximum theoretical delivery capacity 60m³/h), S (S-type distribution valve), E (motor power type), A (design serial number import mark ), 18 (main cylinder stroke), 16 (maximum outlet pressure Mpa).

2. Diesel engine concrete pump

Illustration: Such as HBT60SDA-1816——HBT (trailed concrete pump), 60 (maximum theoretical delivery capacity 60mm³/h), S (S type distribution valve), D (diesel engine power type), A (design serial number import mark), 18 (main cylinder stroke), 16 (maximum outlet pressure Mpa).

3. Truck-mounted concrete pump

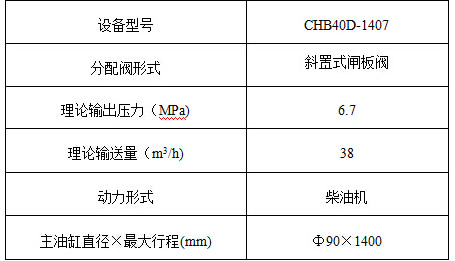

Illustration: The meaning of truck-mounted concrete pump CHB40D-1407 is as follows: CHB (truck-mounted concrete pump), 40 (Maximum theoretical delivery volume 40m3/h), D (diesel engine power type), 14 (main cylinder stroke), 07 (maximum outlet pressure Mpa), the corresponding performance parameters are detailed in the table below:

3. How to install and debug the concrete pump

1. Installation of the concrete pump

The concrete pump supplied by the concrete mixer truck can be installed on-site as long as it can be easily connected and fed; if the concrete is mixed on-site, the location of the mixer should first be determined based on the site and the loading method of the mixer. Then determine the position of the pump according to the discharge height of the mixer and the requirements for pumping and taking over. The installation method is as follows:

(1) First, place the pump on a firm cement floor or stone pier to keep it level, and connect the positioning pins of the four legs of the pump to theLock the safety pin to lift the tire off the ground or remove the tire.

(2) Make a chute between the discharge port of the mixer and the hopper of the pump, so that the material discharged from the mixer can enter the hopper of the pump through the chute. The chute usually uses angle steel as the frame and is welded from 1.5mm thick steel plates. Use supports below the chute to make it firm. For the chute, the slope is required to be appropriate, and the inclination angle is preferably 25 degrees to 40 degrees. There should be a certain space between the chute and the pump hopper to facilitate cleaning of the hopper and screen.

(3) Under normal circumstances, the top of the hopper of the pump needs to be raised by about 20cm, which can increase the volume of the hopper to ensure that the concrete does not flow out (because it is best to unload the material at one time for the forced mixer) , so that the concrete flowing into the hopper is relatively uniform. If the material is discharged in batches, the final concrete coming out will have more stones, which is not good for pumping. If a large-capacity mixer is used, a storage hopper can be made in advance to ensure continuous supply. .)

(4) After the pump is installed in place, ensure that the pump cover door can be opened and closed freely to facilitate maintenance operations.

2. Pipeline layout of concrete pump

(1) The pipeline layout should be as high as possible while ensuring smooth pumping and normal transportation. Shorten its length and reduce bends to reduce conveying resistance.

(2) It is best to connect a straight pipe of more than 2m in front of the tapered pipe before using the bent pipe. It is also necessary to ensure that the axis of the straight pipe coincides with the axis of the tapered pipe and be fixed reliably so that the tapered pipe can It can be quickly put back together after disassembly and cleaning.

(3) Each pipeline must be firmly connected, and a firm fixing device must be installed at the bend. A firm point must be set up every 10m for horizontal pipelines, and the pipeline clamps must be suspended to facilitate removal. , take over the road. Each clamp must be tightened in place to ensure that the joint is tightly sealed and does not leak slurry or water.

(4) Take over according to the on-site construction conditions and combined with the takeover requirements, and arrange the pipelines reasonably to eliminate hidden dangers.

3. Debugging of concrete pumps

(1) After the pump is installed in place, the pump should be inspected as a whole. The inspection content includes : Whether the liquid level in the tank is within the specified range, whether the hydraulic hose joints, pipe clamp fixing seats and other connecting parts are loose, whether there is any oil leakage, whether the connection of the electrical components is disconnected or off-line, whether the contact screws are Loose, and whether there are foreign objects or impurities in the hopper.

(2) Electrical inspection. First, check whether the on-site voltage is (380±10%) V. The pump must be equipped with a special control switch. The specifications of the cables used must be consistent with the main cables on the pump, and the ground wire must be connected as required. Then do the following checks:

A. Turn on the control circuit switch, the power indicator light will be on, and the programmable controller PLC module will be powered on. At this time, observe the indicator lights on the module (respectively start, run and fault), if the start and running lights are on; and the fault light is off, it means it is normal and normal operation can be carried out, otherwise it is abnormal., the pump cannot operate.

B. Press the motor start button to see if the motor’s AC contactor operates according to the program and whether the motor indicator light is on.

C. Press the pumping, anti-pumping, pressure test, and stirring buttons respectively to see if the programmable controller has input and output signals.

(3) If everything above is normal, the pump can start running. During the entire operation, always pay attention to the connections of various parts of the pump, the condition of the high-pressure hoses and various instruments. In case of emergency, directly Press the main stop switch to stop the machine, just in case.

(4) Concrete. After the no-load debugging of the whole machine, you can prepare to pump concrete, but before pumping, you must also: Understand the variety and quality of the coarse aggregate in the concrete, as well as the particle size and gradation, and form a strict labor organization with a reasonable division of labor. , arrange liaison measures, have a dedicated person responsible for supervising the supply situation, and prepare various maintenance tools and cleaning equipment for transportation pipelines, as well as night lights.

(5) Pay attention to the following points when pumping concrete:

A. Start the concrete pump to run dry. If the temperature is low, the dry running time should be longer, and the hydraulic pressure The temperature of the oil must rise to 15 degrees Celsius before it can be pumped.

B. Add a certain amount of clean water to the hopper to warm the hopper, distribution valve and conveying pipeline.

C. Before pumping concrete, 0.5-1m3 of mortar must be pumped; part of the mortar must be retained in the hopper (to the upper and lower parts of the hopper axis), and the concrete must be added to the hopper before pumping together. .

D. During the process of pumping concrete, strict attention should be paid to the actual mixing quality and slump of the concrete. If the mixed concrete does not meet the pumping requirements, it must be discarded.

E. The hopper net should not be filled with concrete. Oversized aggregates and debris on the net must be removed in time. When the mixing shaft in the hopper is stuck and cannot rotate, pumping must be suspended. And reverse the operation in time to troubleshoot the problem. The concrete in the hopper should not be too little to prevent pipeline blockage due to air suction. When the material supply cannot keep up, pumping must be stopped in time.

F. When the pumping operation needs to be interrupted for a long time, the mixing work in the hopper should be stopped, otherwise the coarse aggregate in the concrete will sink. When pumping again, the mixing should be done first, and it must be in the correct position. . Normal pumping can be resumed only after two strokes of anti-pumping operation.

G. During the pumping process, the pressure and lubrication of each instrument on the pump should be frequently observed. If any abnormalities occur, they should be eliminated in time to ensure normal pumping.

4. Pipeline cleaning of concrete pumps

There are two methods for pipe cleaning, namely water washing and air washing:

(1) Water washing: The gap between the cutting ring and the eye plate (for butterfly valve pumps, the plate valve, tie rod and upper and lower wear-resistant plates) is required to be small, a large amount of water is required, and the sealing is strict, so that the water after cleaning the ball cannot Penetrate forward. At the end of water washing, be careful not to let the water in the pipeline flow to the place where the concrete is poured, otherwise it will affect the quality of the concrete. This method is simple to operate,Less dangerous and more commonly used.

(2) Air washing: that is, blowing with compressed air. It is to insert the cleaning ball soaked in water into the air washing joint first, and then connect it to the first straight pipe connected to the variable diameter, and Connect a safety cap to the end of the pipeline (the opening of the safety cap must face downwards). During air washing, the pressure of compressed air must be controlled not to exceed 0.8MPa; the air valve must be opened slowly, and the large air valve can only be opened when the concrete can flow out smoothly; after air washing is completed, the air valve must be closed immediately. Air washing requires an air compressor, which must be operated strictly according to regulations and requires good pipeline sealing. However, air washing cannot clean long pipelines. Long-distance pipelines should be cleaned in sections. This method must be operated with caution. The danger is great, so construction workers should stay away from the exit to prevent pellets or cleaning balls from flying out and injuring people.

If the website content violates your rights, please contact us to delete it。