1. Why does the safety grating keep the red light on?

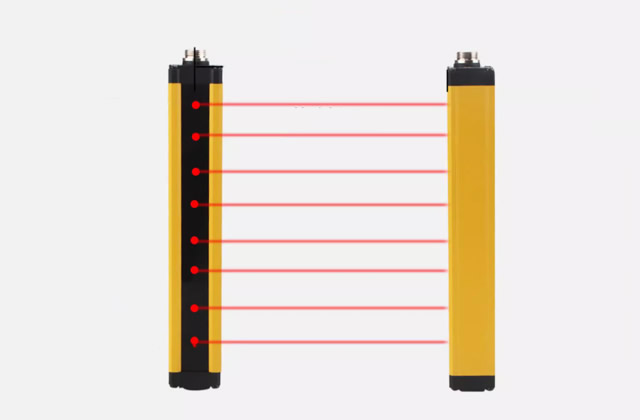

As the name suggests, the safety grating is used for the safety protection of equipment and to protect mechanical operations. personnel’s personal safety. Many customers who use safety gratings for the first time will be confused about how to install the grating so that it can be used normally. When the safety grating is powered on, the emitter flashes three times and then stays on, and the traffic light of the receiver flashes three times at the same time. At this time, the safety grating is in working condition.

There are two situations when the safety grating lights up red: one is when it is working normally, and the other is when a malfunction causes the red light to turn on. When the red light initially lights up, you can detect the infrared sensor. If the grating switches between red light and green light, it means normal use.

When the emitter and receiver enter the working state, the red light of the emitter is always on and the receiver lights green. When the grating is blocked, the light emitter indicator will not change, the light receiver will change from green light to red light, and the number of blocked lights will be displayed on the digital display. When there is no obstruction, the receiver returns to the green light.

2. Common faults of safety light gratings and self-troubleshooting methods

1. Light grating No action

Cause 1: Insufficient power supply voltage. Solution: Ensure that the supply voltage meets the rated requirements.

Cause 2: The cable is not wired correctly. Solution: Check and reconnect the cables.

Cause 3: The rated detection distance is exceeded. Solution: Make sure the light grid is used within the specified detection distance.

2. Occasionally not moving

Cause 1: There is dust on the detection surface. Solution: Use a soft brush or rag to remove dust.

Cause 2: Connector connection failure. Solution: Check the connector and make sure there is a good connection.

3. There is no control output and remains closed

Cause 1: The rated detection distance is exceeded. Solution: Make sure to use the grating within the rated detection distance.

Cause 2: There are obstacles blocking the light between the emitter and the receiver. Solution: Remove obstacles and ensure unobstructed light.

Cause 3: There are strong interference sources around, such as motors, generators, high-voltage lines, etc. Solution: Stay away from sources of strong interference and ensure a clean working environment.

4. Synchronization line LED display failure

Synchronization line connection problem or line interruption, emitter or receiver synchronization line circuit failure. Solution: Check the synchronization line connection and make sure it is normal.

5. LED displays over-current fault

Cause 1: The control output is short-circuited. Solution: Check the wiring to make sure there are no short circuits.

Cause 2: Load capacity exceeded. Solution: Check the load capacity to ensure it does not exceed the rated range.

The above methods can be used by users to troubleshoot some common safety grating faults on site. If the problem still exists or further support is needed, please contact the manufacturer’s after-sales service.

If the website content violates your rights, please contact us to delete it。