1. Why use visual sensors

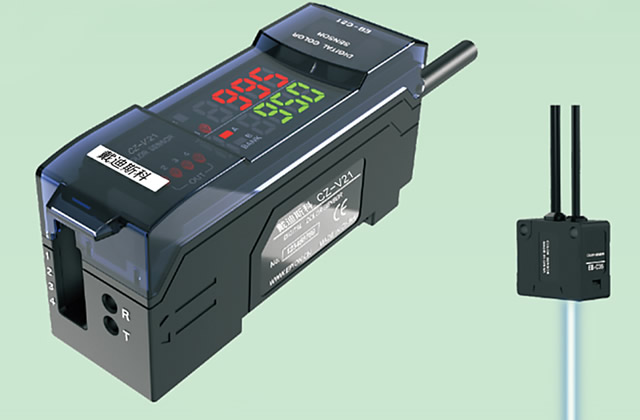

In factory automation, sensors are usually used in work cells to collect data for inspection, or to trigger other equipment. These sensors fall into several categories: optoelectronic, fiber optic, close range, ultrasonic, and visual, which are all common sensor types. Today let’s first learn about vision sensors.

Sensors are often used in work cells to collect data for inspection, or to trigger other devices. Vision sensors are designed to handle a wide range of variations. This enables operators to use them in pre-configured units without having to make a number of expensive and time-consuming changes.

2. How to use vision sensors

The low cost and ease of use of vision sensors has attracted machine designers and process engineers to integrate them into a variety of applications that once relied on humans, multiple photoelectric sensors, or no inspection at all. Industrial applications for vision sensors include inspection, metrology, measurement, orientation, defect detection and sorting. The following are some usage examples:

1. In the automobile assembly plant, check whether the glue beads applied by the robot to the door frame are continuous and have the correct width. At the bottling plant, verify that the bottle caps seal correctly, that the filling level is correct, and that no foreign matter has fallen into the bottle before capping.

2. In the packaging production line, ensure that the correct packaging label is pasted at the correct location.

3. In the pharmaceutical packaging production line, check whether there are any damaged or missing tablets in the blister packaging of aspirin tablets.

4. In metal stamping companies, stamping parts are inspected at a speed of more than 150 pieces per minute, which is more than 13 times faster than manual inspection.

If the website content violates your rights, please contact us to delete it。